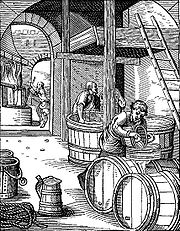

Brewing

The process of making beer is known as brewing. A dedicated building for the making of beer is called a brewery, though beer can be made in the home and has been for much of beer's history. A company which makes beer is called either a brewery or a brewing company. Beer made on a domestic scale for non-commercial reasons is classed as homebrewing regardless of where it is made, though most homebrewed beer is made in the home. Brewing beer is subject to legislation and taxation in developed countries, which from the late 19th century, largely restricted brewing to a commercial operation only. However, the UK government relaxed legislation in 1963, followed by Australia in 1972, and the USA in 1979, allowing homebrewing to become a popular hobby.[20]

The purpose of brewing is to convert the starch source into a sugary liquid called wort and to convert the wort into the alcoholic beverage known as beer in a fermentation process effected by yeast.

The first step, where the wort is prepared by mixing the starch source (normally malted barley) with hot water, is known as "mashing". Hot water (known as "liquor" in brewing terms) is mixed with crushed malt or malts (known as "grist") in a mash tun.[21] The mashing process takes around 1 to 2 hours,[22] during which the starches are converted to sugars, and then the sweet wort is drained off the grains. The grains are now washed in a process known as "sparging". This washing allows the brewer to gather as much of the fermentable liquid from the grains as possible. The process of filtering the spent grain from the wort and sparge water is called wort separation. The traditional process for wort separation is lautering, in which the grain bed itself serves as the filter medium. Some modern breweries prefer the use of filter frames which allow a more finely ground grist. Most modern breweries use a continuous sparge, collecting the original wort and the sparge water together. However, it is possible to collect a second or even third wash with the not quite spent grains as separate batches. Each run would produce a weaker wort and thus a weaker beer. This process is known as second (and third) runnings. Brewing with several runnings is called parti gyle brewing.

The sweet wort collected from sparging is put into a kettle, or "copper", (so called because these vessels were traditionally made from copper) and boiled, usually for about one hour. During boiling, water in the wort evaporates, but the sugars and other components of the wort remain; this allows more efficient use of the starch sources in the beer. Boiling also destroys any remaining enzymes left over from the mashing stage. Hops are added during boiling in order to extract bitterness, flavour and aroma from them. Hops may be added at more than one point during the boil. The longer the hops are boiled, the more bitterness they contribute, but less of the hop flavour and aroma remains in the beer.

After boiling, the hopped wort is now cooled, ready for the yeast. In some breweries, the hopped wort may pass through a hopback, which is a small vat filled with hops, to add aromatic hop flavouring and to act as a filter; but usually the hopped wort is simply cooled for the fermenter, where the yeast is added. During fermentation, the wort becomes beer in a process which requires a week to months depending on the type of yeast and strength of the beer. In addition to producing alcohol, fine particulate matter suspended in the wort settles during fermentation. Once fermentation is complete, the yeast also settles, leaving the beer clear.

Fermentation is sometimes carried out in two stages, primary and secondary. Once most of the alcohol has been produced during primary fermentation, the beer is transferred to a new vessel and allowed a period of secondary fermentation. Secondary fermentation is used when the beer requires long storage before packaging or greater clarity. When the beer has fermented, it is packaged either into casks for cask ale or kegs, aluminum cans, or bottles for other sorts of beer.

From Wikipedia, the free encyclopedia

Click Here..to see Beer Tender